Our Products

We carry large stocks of EMICO Ball valves. Manual ball valves are AGA Certified to AS4617 and Actuated Shut-off & Vent valves to AS4629. For details, please contact us at sales@emicovalves.com.

View our current Emico Valve Stocks (PDF) or click on the logos below to browse through our wide range of Valves, Actuators & Controls.

Emico

EMICO Australia Pty Ltd is a subsidiary and sales/marketing office of EMICO (Eayuan Metals Industrial) Taiwan, based in Melbourne, Australia. The company was established in 2008 to serve the Australian, New Zealand and Pacific Rim markets for the rapidly-expanding range of ball valves and actuators, manufactured in Taiwan and China, for the world market.

Production range

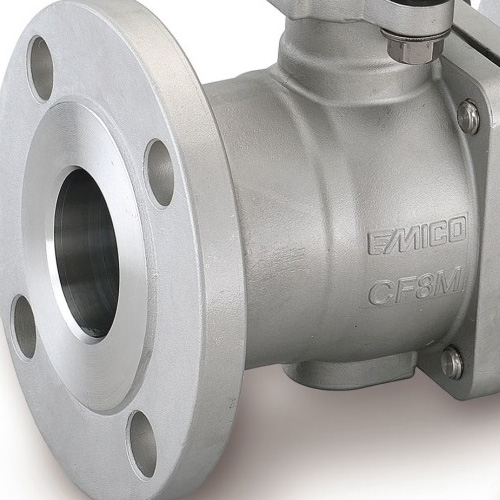

EMICO’s ball valves are made by investment casting (lost wax process) from size 1/4″ up to 4″ and sand casting or stack shell casting from 4″ to 12″. High pressure classes are supplied in forged construction.

Ball valves are supplied in various configurations: 1-piece, 2-piece & 3-piece with threaded, socket weld, butt weld or flanged ends in Class 150, Class 300, Class 800, Class 900, Class 1500 and Class 2500 ratings.

Standard materials offered are stainless steel 316 and carbon steel in WCB or A105 to applicable ASTM standards. Other materials introduced to the range of supply are Alloy 20/CN7M, Hastelloy C, Duplex and Super Duplex.

EMICO also produce a range of Oil Field valves and Sanitary Valves.

EMICO produce a wide product range in sizes 15mm to 600mm (2″ to 24″) and in various types including:

Ball Valves – Floating and Trunnion designs. Uni-Body, Split 2-pce Body, 3-pce Body, Fire Safe and Non-Fire Safe, Cryogenic, Metal seat, Soft Seat.

Fig. EA 901 / EA903 / EA906 / EA909 / EA915 – Forged Trunnion

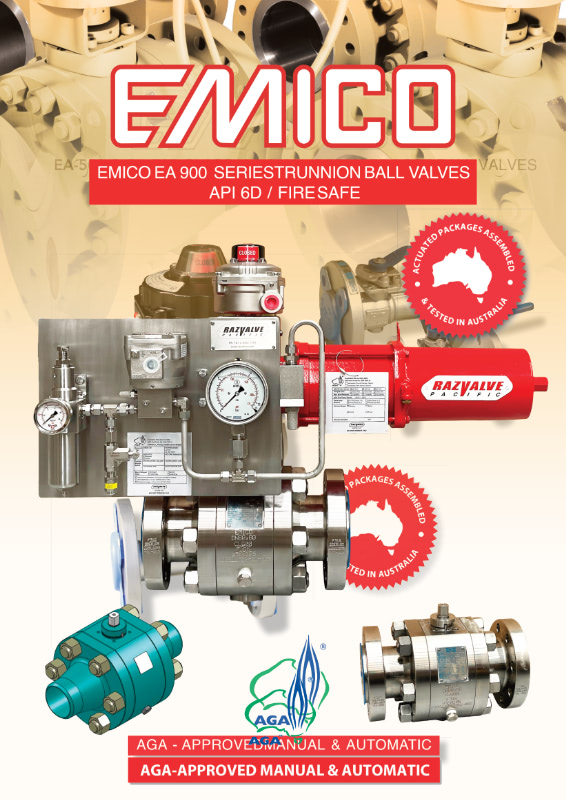

Fig. EA 900 Series – Cast Trunnion

Fig EA 503C / EA 503F & EA 507C / EA507F – Uni-Body

Fig EA 25AC / EA25AF & EA25JC / EA25JF – Split Body, Fire Safe

Fig EA 402F – Split Body, Non-Fire Safe

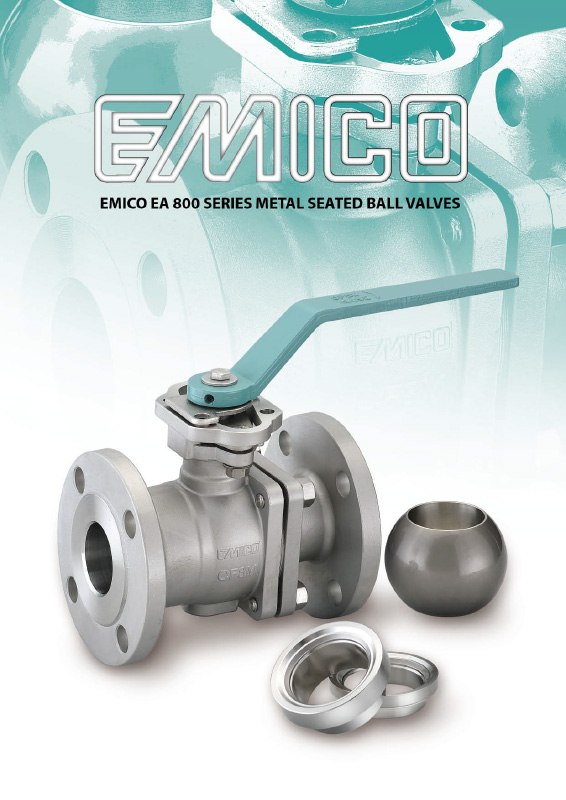

Fig EA 801 / 803 – Split Body, Metal Seat Flanged

Fig. EA 309C & EA309F – Class 800

Fig. EA 313C & EA313F – Class 800

Fig. EA 310C & EA310F – Class 1500

Fig. EA 311 – Class 900 Metal Seat

Fig. EA 39C – Class 800 Cryogenic

Fig. EA 39C – Flanged ANSI 600 Cryogenic

Fig. EA 305C & EA305A – AGA AG-201 approved

EA305C, 3-Pce design, with pup extensions and heavy-duty stem adaptor

Fig. P134 / P135 – Forged Class 800, 1500 & 2500

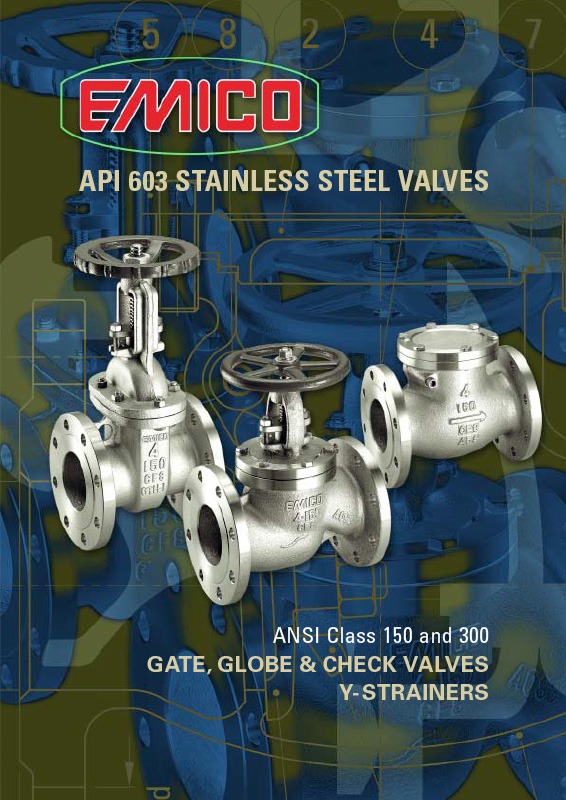

Gate, Globe & Check valves – Cast and Forged. Cast valves are manufactured in sizes 50mm and above in Stainless Steel, Carbon Steel and other materials, all flanged ANSI 150, 300, 600, 900, 1500 & 2500. The forged range is available 15mm ~ 50mm.

Fig EAS-105 & EAS-115 – Stainless Steel Gate

Fig EAS-205 & EAS-215 – Stainless Steel Globe

Fig EAS-306 & EAS-315 – Stainless Steel Swing Check

Fig K7- Wafer & Lugged Check

Cast Steel Flanged Gate, Globe & Check valves

Forged Gate, Globe & Check valves

Pneumatic Actuators – Rack & Pinion in both Spring Return and Double Acting.

Other application areas include water, mining, process, etc.

EMICO was the first ball valve manufacturer in Taiwan to obtain the ISO 9002 Quality Assurance System, and in the year 2000 further obtained ISO 9001 certification cross approved with TUV DIN EN ISO 9001 certification.

EMICO is authorised licensee to use API 6D and certified to PED, CE, ATEX, TA-Luft and UL listed.

EMICO is certified to Australian Gas Association (AGA) AG-214 for its range of EA-305 3-pce fire safe ball valves.

Fire safe designs include: 1-pc EA-108, 2-pc EA-25A, 3-pc EA-305, EA309, EA310 & P135. These valves are fire safe to API 607 4th & 5th editions fire test requirements and tested and certified by Southwest Research Institute (SwRI) in Texas, USA and TU-Luft.

EMICO has an established Engineering department of engineers, technicians and an R&D centre with years of experience in the manufacture of quality ball valves.

All valves are fully traceable and certified to EN 10204-2004 3.1 (chemical, mechanical, hydrostatic & pneumatic pressure tests) and can be supplied with NDE performed to ASME B16.34 international standards. Valves are tested and certified to API 598.

You will be satisfied with EMICO’s products which are reasonably priced and with an excellent reputation, over the years, for superior quality and on-time shipment.

- EMICO EA 503 507 Feb 2024

- EMICO EA 25 Feb 2024

- Emico K7 Series Dual Plate Check Valve

- EMICO EA 900 Catalog Feb 2024

- Emico EA 800 Series Metal Seated Ball Valves

- EA Series SR & DA Pneumatic Actuators

- API 603 Stainless Steel Valves

- EMICO EA 309 Feb 2024

- EMICO EA 305 Feb 2024

- EMICO Cryogenic Ball-Valves

- EMICO 251, 253 & 256 HP Ball valves

Trunnion Ball

Fig. EA 901 / EA903 / EA906 / EA909 / EA915 – Forged Trunnion

Forged 3-Pce split body, trunnion ball valve, full port or reduced port, soft seat, double block & bleed, anti-static, sealant injection facility, blow-out proof stem, automatic internal relief, NACE MR 01-75, Viton AED o-rings, graphite packing, locking facility, lever or gear hand wheel operated or actuated.

Size Range: 50mm ~ 300mm

Rating: Flanged RF Class 150 ~ 1500

Design: API 6D / ISO 14313 & ASME B16.34

Fire Safe: API 607 Ed 5 / ISO 10497-5:2004

Face to Face: ASME B16.10

Flange Dimensions: ASME B16.5

Materials (ASTM): A105, A350 LF2, A182 F316/L, Super Duplex

Pressure Testing: API 598 / API 6D

Fig. EA 900 Series – Cast Trunnion

Cast 2-pce, split body, trunnion ball valve, full port or reduced port, soft seat, double block & bleed, anti-static, sealant injection facility, blow-out proof stem, automatic internal relief, vent relief valve, NACE MR 01-75, Viton o-rings, graphite packing, lever or gear hand wheel operated.

Size Range: 50mm ~ 600mm|

Rating: Flanged RF Class 150 & 300

Design: API 6D / ISO 14313 & ASME B16.34

Fire Safe: API 607 Ed 5 / ISO 10497-5:2004

Face to Face: ASME B16.10

Flange Dimensions: ASME B16.5

Materials: A216 WCB, A351 CF8M & other cast materials

Pressure Testing: API 598 / API 6D

Floating Ball

Fig EA 503C / EA 503F & EA 507C / EA507F – Uni-Body

Cast 1-Pce, end entry, reduced port, soft seat, floating ball valve, anti-static, blow-out proof stem, locking facility, lever or gear hand wheel operated or actuated.

Size Range: 15mm ~ 250mm

Rating: Flanged RF Class 150 & 300

Design: ASME B16.34

Fire Safe: API 607 Ed 5 / ISO 10497-5:2004

Face to Face: ASME B16.10

Flange Dimensions: ASME B16.5

Materials (ASTM): A216 WCB, A351 LCB, Super Duplex

Pressure Testing: API 598

Fig EA 25AC / EA25AF & EA25JC / EA25JF – Split Body, Fire Safe

Cast 2-Pce, split body, full port, soft seat, floating ball valve, anti-static, blow-out proof stem, locking facility, lever or gear hand wheel operated or actuated.

Size Range: 15mm ~ 250mm

Rating: Flanged RF Class 150 & 300

Design: ASME B16.34

Fire Safe: API 607 Ed 4 / ISO 10497-5:2004

Face to Face: ASME B16.10

Flange Dimensions: ASME B16.5

Materials (ASTM): A216 WCB, A351 LCB, A351 CF8M, Super Duplex

Pressure Testing: API 598

Fig EA 402F – Split Body, Non-Fire Safe

Cast 2-Pce, split body, full port, soft seat, floating ball valve, anti-static, blow-out proof stem, locking facility, lever or gear hand wheel operated or actuated.

Size Range: 15mm ~ 200mm

Rating: Flanged RF Class 150

Design: ASME B16.34

Fire Safe: Fire Safe Design

Face to Face: ASME B16.10

Flange Dimensions: ASME B16.5

Materials (ASTM): A351 CF8M

Pressure Testing: API 598

Fig EA 801 / 803 – Split Body, Metal Seat Flanged

Cast 2-Pce, split body, full port, metal seat, floating ball valve, anti-static, blow-out proof stem, locking facility, lever or gear hand wheel operated or actuated.

Size Range: 15mm ~ 100mm

Rating: Flanged RF Class 150 & 300

Design: ASME B16.34

Fire Safe: Inherently Fire Safe

Face to Face: ASME B16.10

Flange Dimensions: ASME B16.5

Materials (ASTM): A216 WCB, A351 CF8M & other cast materials

Pressure Testing: API 598

Fig. EA 309C & EA309F – Class 800

3-Pce split body, floating ball valve, full port, soft seat, anti-static, blow-out proof stem, NACE MR 01-75, Viton AED o-rings, graphite packing, locking facility, lever operated or actuated.

Size Range: 15mm ~ 50mm

Rating: Class 800

Design: EN 12516

Shell Wall Thickness: ASME B16.34

Fire Safe: API 607 Ed 4 / ISO 10497-5:2004

Face to Face: Manufacturers standard

End Connections: NPT (ASME B1.20.1) & SW (ASME B16.11)

Materials (ASTM): A216 WCB, A351 CF8M, Super Duplex

Pressure Testing: API 598

Fig. EA 313C & EA313F – Class 800

Forged 3-Pce split body, floating ball valve, full port, soft seat, anti-static, blow-out proof stem, NACE MR 01-75, graphite packing, locking facility, lever operated or actuated.

Size Range: 15mm ~ 50mm

Rating: Class 800

Design: EN 12516

Shell Wall Thickness: ASME B16.34

Fire Safe: API 607 Ed 4 / ISO 10497-5:2004

Face to Face: Manufacturers standard

End Connections: NPT (ASME B1.20.1) & SW (ASME B16.11)

Materials (ASTM): A216 WCB, A351 CF8M, Super Duplex

Pressure Testing: API 598

Fig. EA 310C & EA310F – Class 1500

3-Pce split body, floating ball valve, full port, soft seat, anti-static, blow-out proof stem, NACE MR 01-75, Viton AED o-rings, graphite packing, locking facility, lever operated or actuated.

Size Range: 15mm ~ 50mm

Rating: Class 1500

Design: ASME B16.34

Shell Wall Thickness: ASME B16.34

Fire Safe: API 607 Ed 5 / ISO 10497-5:2004

Face to Face: Manufacturers standard

End Connections: NPT (ASME B1.20.1) & SW (ASME B16.11)

Materials (ASTM): A216 WCB, A351 CF8M, Super Duplex

Pressure Testing: API 598

Fig. EA 311 – Class 900 Metal Seat

3-Pce split body, floating ball valve, full port, metal seat, anti-static, blow-out proof stem, NACE MR 01-75, graphite packing, locking facility, lever operated or actuated.

Size Range: 15mm ~ 50mm

Rating: Class 900

Design: ASME B16.34

Shell Wall Thickness: ASME B16.34

Fire Safe: Inherently Fire Safe

Face to Face: Manufacturers standard

End Connections: BW

Materials (ASTM): A216 WCB, A351 CF8M, Super Duplex

Pressure Testing: API 598

Fig. EA 39C – Class 800 Cryogenic

3-Pce split body, cryogenic floating ball valve, full port, soft seat, anti-static, bonnet extension column for -196° C service, blow-out proof stem, o-rings, graphite packing, locking facility, lever operated or actuated.

Size Range: 15mm ~ 50mm

Rating: Class 800

Design: EN 12516

Shell Wall Thickness: ASME B16.34

Fire Safe: API 607 Ed 4 / ISO 10497-5:2004

Face to Face: Manufacturers standard

End Connections: NPT (ASME B1.20.1) & SW (ASME B16.11)

Materials (ASTM): A216 WCB, A351 CF8M, Super Duplex

Pressure Testing: API 598

Cryogenic Testing: BS 6364

Fig. EA 39C – Flanged ANSI 600 Cryogenic

3-Pce split body, cryogenic floating ball valve, full port, soft seat, anti-static, bonnet extension column for -196° C service, blow-out proof stem, o-rings, graphite packing, locking facility, lever operated or actuated.

Size Range: 15mm ~ 50mm

Rating: ASME 600 Flanged

Design: EN 12516

Shell Wall Thickness: ASME B16.34

Fire Safe: API 607 Ed 4 / ISO 10497-5:2004

Face to Face: ASME B16.10

End Connections: ASME B16.5

Materials (ASTM): A216 WCB, A351 CF8M, Super Duplex

Pressure Testing: API 598

Cryogenic Testing: BS 6364

Fig. EA 305C & EA305A – AGA AG-201 approved

3-Pce split body, floating ball valve, full port, soft seat, anti-static, blow-out proof stem, graphite packing, locking facility, lever operated or actuated.

Size Range: 15mm ~ 50mm

Rating: 1000psi

Fire Safe: API 607 Ed 4 / ISO 10497-5:2004

Face to Face: Manufacturers standard

End Connections: NPT (ASME B1.20.1) & SW (ASME B16.11)

Materials (ASTM): A216 WCB, A351 CF8M

Pressure Testing: API 598

Australian Gas Association Approval: AG-201 No. 5547

EA305C, 3-Pce design, with pup extensions and heavy-duty stem adaptor

Fig. P134 / P135 – Forged Class 800, 1500 & 2500

Forged body, floating ball valve, full port or reduced port, soft seat, anti-static, blow-out proof stem, graphite packing, locking facility, lever operated.

Size Range: 15mm ~ 50mm

Seat Material: Nylon, Devlon, Peek

Rating: Class 800, 1500 & 2500

Fire Safe: API 607 Ed 4

Face to Face: Manufacturers standard

End Connections: NPT (ASME B1.20.1) & SW (ASME B16.11)

Materials (ASTM): A105N, LF2, F316/L

Pressure Testing: API 598

Stainless Steel Gate, Globe, Check

Fig EAS-105 & EAS-115 – Stainless Steel Gate

Flanged stainless steel gate valve, bolted bonnet, integral seat, outside screw & yoke, rising stem, non-rising hand wheel

Size Range: 15mm ~ 600mm=

Rating: Flanged RF Class 150 & 300

Design: API 603

P/T Rating: ASME B16.34

Face to Face: ASME B16.10

Flange Dimensions: ASME B16.5

Materials (ASTM): A351 CF8M

Pressure Testing: API 598

Fig EAS-205 & EAS-215 – Stainless Steel Globe

Flanged stainless steel globe valve, bolted bonnet, integral seat, outside screw & yoke, rising stem & hand wheel

Size Range: 15mm ~ 600mm

Rating: Flanged RF Class 150 & 300

Design: ASME B16.34

P/T Rating: ASME B16.34

Face to Face: ASME B16.10

Flange Dimensions: ASME B16.5

Materials (ASTM): A351 CF8M

Pressure Testing: API 598

Fig EAS-306 & EAS-315 – Stainless Steel Swing Check

Flanged stainless steel swing check valve, bolted cover, integral seat

Size Range: 15mm ~ 600mm

Rating: Flanged RF Class 150 & 300

Design: ASME B16.34

P/T Rating: ASME B16.34

Face to Face: ASME B16.10

Flange Dimensions: ASME B16.5

Materials (ASTM): A351 CF8M

Pressure Testing: API 598

Dual Plate Check

Fig K7- Wafer & Lugged Check

Wafer & Lugged Dual & Single Disc check valve. Standard and Retainerless Designs. Cast or Forged body available

Size Range: 50mm ~ 600mm

Rating: Flanged RF & RTJ Class 150 ~ 1500

Design: API 594, API 6D

P/T Rating: ASME B16.34

Face to Face: API 594

Flange Dimensions: ASME B16.5

Materials (ASTM): A216 WCB, A351 CF8M & other materials

Pressure Testing: API 598

Gate Globe Check

Cast Steel Flanged Gate, Globe & Check valves

Gate valves: bolted bonnet, all API trims, replaceable seat, outside screw & yoke, rising stem & hand wheel

Globe valves: bolted bonnet, all API trims, replaceable seat, outside screw & yoke, rising stem, non-rising hand wheel

Check valves: Swing type, bolted bonnet, all API trims, replaceable seat.

Size Range: 50mm ~ 600mm

Rating: Flanged RF Class 150 ~ 1500

Design: API 600 / BS1414, BS 1873, BS 1868

P/T Rating: ASME B16.34

Face to Face: ASME B16.10

Flange Dimensions: ASME B16.5

Materials (ASTM): A216 WCB, A351 CF8M & other materials

Pressure Testing: API 598

Forged Gate, Globe & Check valves

Forged steel gate, globe & check valve, bolted cover, all API trims. Gate valve: Reduced & Full Port

Size Range: 15mm ~ 50mm

Rating: Class 800 & 1500 (NPT, SW, BW, etc)

Flanged ends: RF/RTJ Class 150 ~ 2500

Design: API 602/BS 5352

P/T Rating: ASME B16.34

Face to Face: ASME B16.10 (for flanged), manufacturers standard for SW / NPT

Flange End Dimensions: ASME B16.5

Materials (ASTM): A105N, F316/L, & other forged materials

Pressure Testing: API 598

Pneumatic Actuator

Pneumatic Actuator

EMICO’s EA Series pneumatic actuators are available in Spring Return (fail open or fail close) as well as Double Acting types.

These actuators feature a top-mounted position indicator (for open & close positions) as well as open & close adjustments as standard supply.

Features include:

- Visual position indicator (yellow & black) and drilling to NAMUR standard for mounting accessories such as Limit Switch, Positioner, etc.

- Travel adjustment external travel stop bolts that allow precise and easy adjustments to ± 5° in both open and close positions.

- High performance pre-loaded, coated stainless steel springs in a number of spring options to meet various torques and pressures with the same actuator size.

- Fourteen models in Spring Return as well as Double Acting to meet varying torques and air-line pressures.

- Actuator body in extruded aluminium alloy, hard anodized followed by polyester powder coating. Other coatings such as PTFE or nickel plated are available on request. Actuators can also be supplied in Stainless Steel 304 or 316 materials.

- The actuator end caps are die-cast aluminium anodized and powder coated. Other coatings and material available as per body supply.

Foundry

In 2012, EMICO set up it’s own state-of-the art investment casting foundry in Taiwan, adjacent to their main valve manufacturing facility, subsequently obtaining approvals and certification including ISO 9001, PED CE and DNV-GL for marine service castings.

Additional to their long-established range of industrial and High Performance valves up to Pressure Class 1500, Emico now offers high quality investment castings to other valve makers, pump manufacturers, automotive and any industry requiring precision cast high-alloy components.

Emico specialises in the investment-casting of all grades of Stainless Steel, including CN7M (Alloy 20). Also, standard and low-temperature carbon steel & other castable materials. Emico supplies castings in the machined or un-machined condition, from small intricate components to a maximum single-piece weight of 120 kgs.

Manufacture is based on the close-tolerance investment casting process, and the castings produced are of the highest quality and tolerance, impossible to achieve by any other casting method. In-house precision-finish machining on the latest machinery is also available when specified. Components of complex shape, thin wall section and fine surface-finish are ideally-suited to the investment-casting method and Emico’s in-house QA and QC systems verify their compliance.